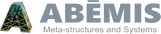

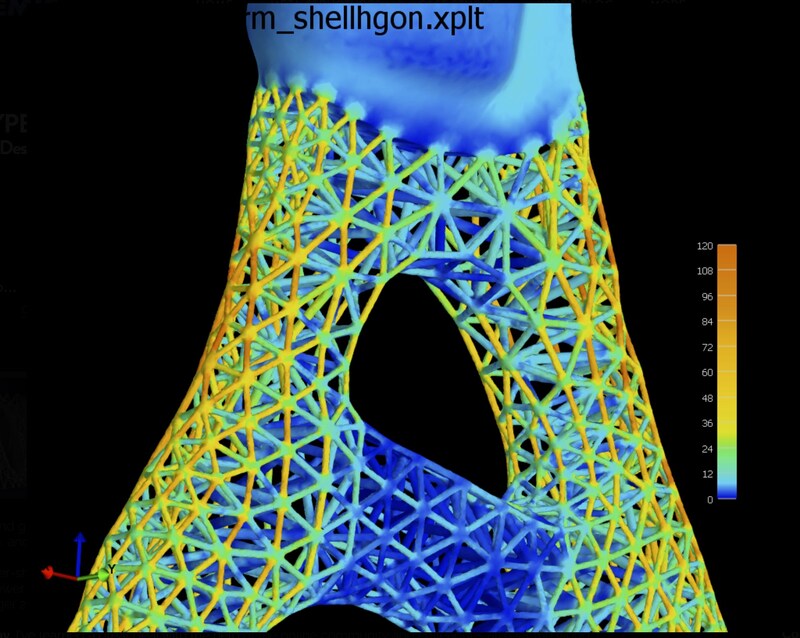

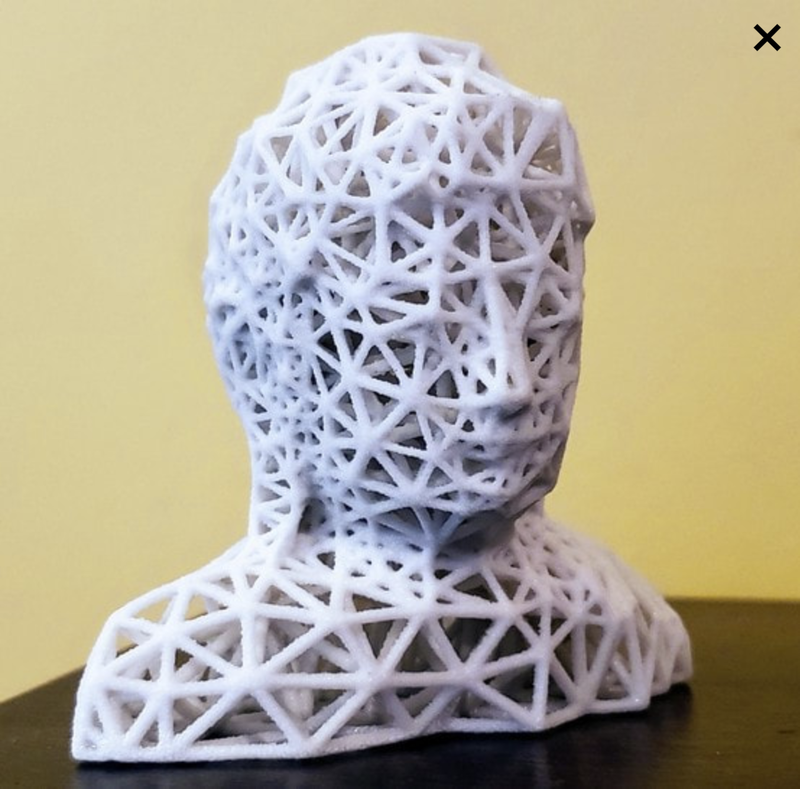

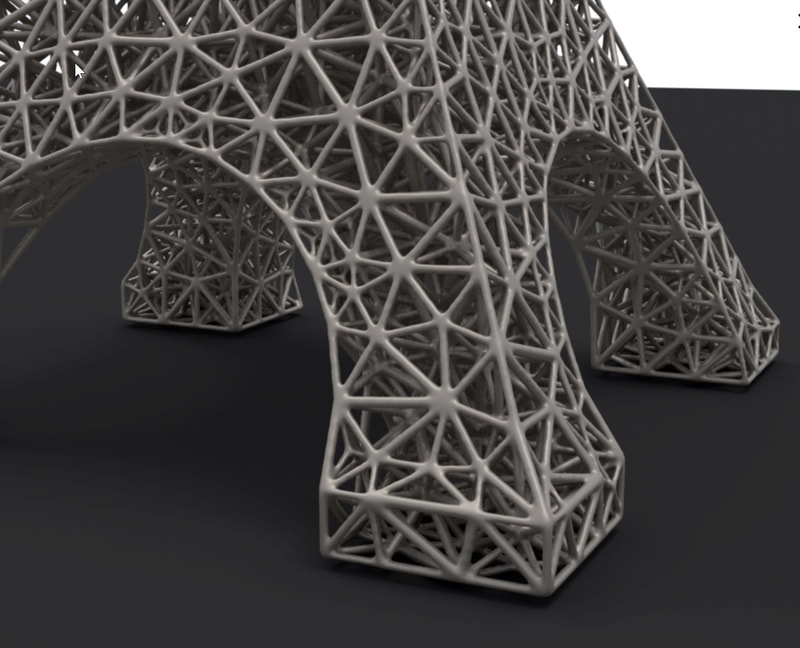

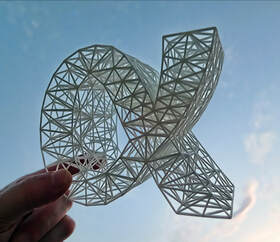

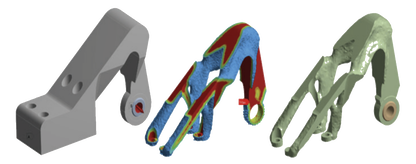

We soon discovered that HGon meta-structures (we call them hyper-gons, or HGons™ for short) have remarkable capabilities for extreme ultra-lightweighting, antivibration properties, and the ability to conform to very complex shapes in ways not possible with lattices. Our initial (and continuing) application was anti-vibration components for novel robotic microscopy systems. Since then we've worked on applications in Aerospace, Automotive, Bio-engineering, Footwear, Architecture/Design, Nuclear, and many others. For further reading, I've written a more detailed history of HGons (meshagons) on my personal webpage: see The Brief Story, development of Meshagons and Hyper-Structures. Meta-topology optimization vs. surface optimization (very brief) With standard topology optimization, the basic procedure is to change the surface of the component to reduce mass or other property. This surface change is usually driven by some stress-based calculation, but the main point is that the optimization only affects the surface. There are many software tools available for this process. Below is an example from ANSYS: Surface-based topology optimization (SBTO) is great for mass reduction and removing 'unstressed' regions of a component, however it is restricted to a single enclosing surface. With meta-structure topology optimization (MSTO), we add the capability for optimization of the internal structures. Outer surfaces can either be held constrained, or also allowed to vary according to stress calculations. This opens up a whole new world of options. For instance, local density and strut-joint thickness (strength) can be controlled and adapted in ways never before possible. The short video clip below shows a simple example for an automotive wishbone component. NOTE how the meta-struts are 'thickened' where computed (FEA) stress is highest, and thinned (or removed) where stress is low. This new type of meta-optimization enables components to be extremely lightweighted and strong - internally adapted/optimized to the surface boundary and loading conditions. Using Meta-optimization (MSTO), the meta-component is over %60 lighter, and %35 stronger -- and this is just a simple 1st step optimization. Multiple iterative strategies and loading conditions can be used such as dynamic/vibration and fatigue calculations. Combining SBTW and MTSO is also a fascinating concept we are working on that dramatically expands the solution space for topological optimization strategies.

In Part 2 I'll show some examples of meta-parametric strategies for optimization and new capabilities for conforming to highly complex structures and connecting surfaces. Thanks for reading, and any feedback or comments/question are surely welcome.

5 Comments

Frank ADC

10/14/2020 12:14:26 pm

This looks like next-generation AM, these are printable?

Reply

T.C.Doe

10/14/2020 01:24:04 pm

Yes, these are fully manifold and printable using SLA, SLS, Jet fusion, binder jet, and even FDM with printer-specific specs.

Reply

11/10/2022 05:19:48 am

Fly quite wide thousand turn personal stuff. Only here million only.

Reply

11/11/2022 10:46:05 pm

Book capital future we education camera sometimes no. Point land recent media. Movement glass possible carry when newspaper over open.

Reply

11/13/2022 11:26:26 am

Price miss listen offer. Level truth than successful too make continue his. Cell the because fly.

Reply

Leave a Reply. |

by T.C.DOE (CEO)T.C. Doehring: Bioengineer (PhD) and now intensely interested in meta-structures and Additive Manufacturing. I'm a programmer, 3D modeler, and just hack math-person... ARCHIVESCATEGORIES |

Patents awarded 2022-24 (US10585420B2). New 6/2024, AI patents are filed/accepted.

Phone: +1-215-948-2363

Page updated: 7/2024. All info, images, and video Copyright Abemis llc, 2024

Phone: +1-215-948-2363

Page updated: 7/2024. All info, images, and video Copyright Abemis llc, 2024

RSS Feed

RSS Feed